Project Milestones

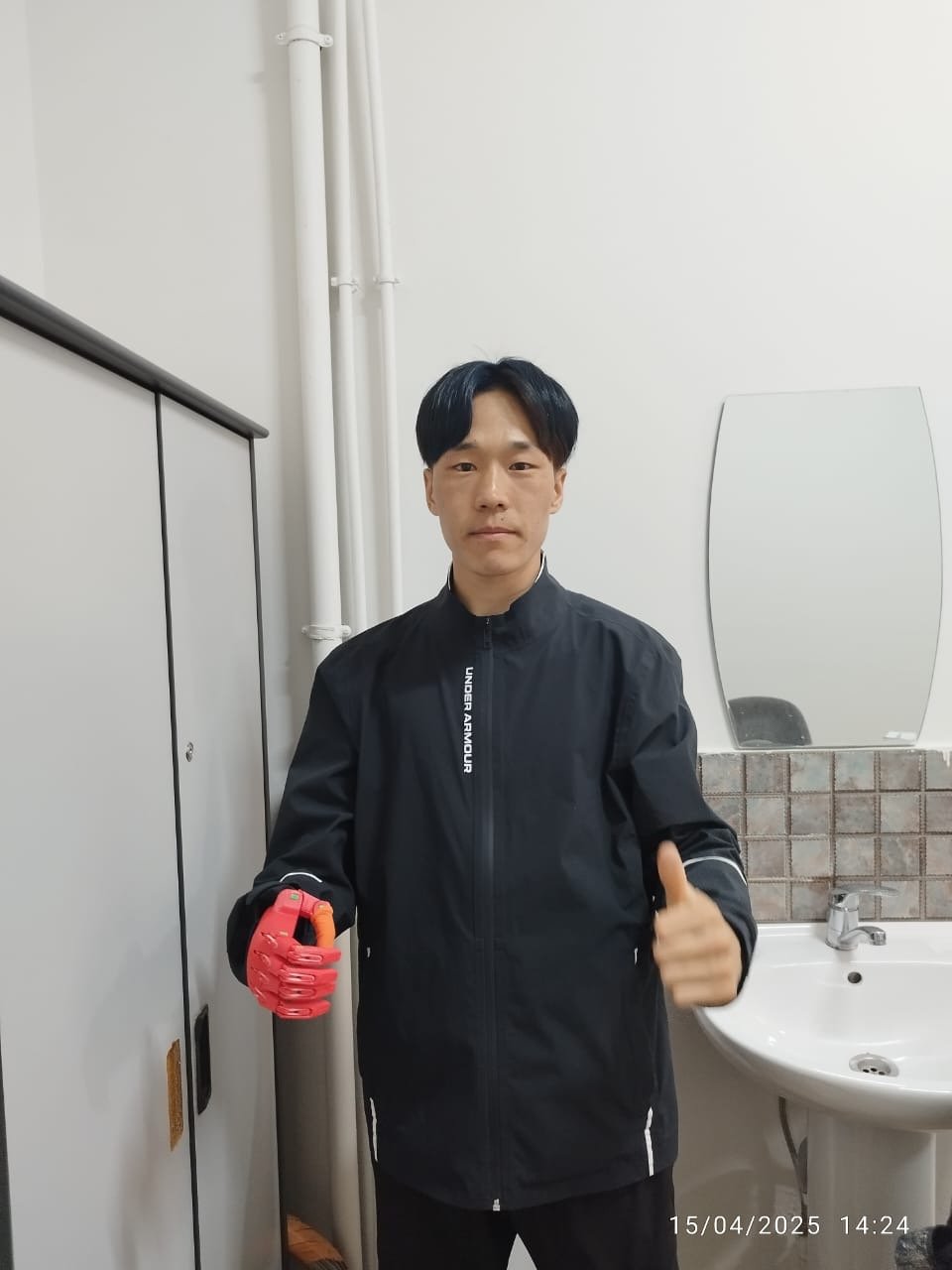

Sustainable Production of Custom Prosthetic Hands in Mongolia!

One of the primary goals of the Mongolian Prosthetics Fulbright Project has been successfully achieved! After months of research, collaboration, and invaluable partnerships, we have developed and introduced a procedure to create articulated, custom hand prosthetics in Mongolia in less than two days for under $40.

With the support of the National Rehabilitation Center of Mongolia, the Oddariya Foundation, and the Fulbright Program, we have produced and tested several devices. These prosthetics have been proven to withstand Mongolia’s unique environmental conditions while significantly improving patients' ability to perform everyday tasks.

A Simple Yet Impactful Innovation

One of the most exciting aspects of this achievement is its accessibility:

Quick to Learn: The process can be mastered with just 1–2 days of training

Available Equipment: Uses tools already present in all seven publicly funded prosthetics workshops in Mongolia

Major Upgrade: Replaces non-functional silicone sleeves with articulated, usable prosthetics

Low Cost: Costs nearly the same as the silicone models but provides greater functionality and dignity

By providing usable, articulated prosthetic hands, we are not only improving the quality of life for recipients but also helping to reduce stigma and promote inclusivity for individuals with limb differences in Mongolian society.

Key Stats:

Cost: Less than $40

Production Time: 2 days (from scan to fitting)

Equipment: One FDM 3D printer

Assembly: One person can make it from start to finish

This breakthrough means that more individuals in need—especially in underserved communities—can now access functional prosthetics without the financial burden of traditional options. By leveraging affordable materials and open-source designs, we’re proving that practical, life-changing prosthetics don’t have to come at a high price.

This is just the beginning! We are excited to keep innovating and expanding access to prosthetic solutions in Mongolia and beyond.

Peel 3D Donates Peel 1 Scanner to Mongolian Prosthetics Project — Expanding Access and Impact

We are thrilled and extremely grateful to announce a significant milestone in the Mongolian Prosthetics Project: Peel 3D has officially and permanently donated a Peel 1 handheld 3D scanner to support our mission of delivering low-cost, custom-fit prosthetic solutions across Mongolia.

A Game-Changer in Accessibility and Precision

The Peel 1 scanner is a professional-grade, handheld device renowned for its precision, durability, and user-friendly interface. With an accuracy of up to 0.25 mm, it allows us to capture highly detailed 3D models of residual limbs—rapidly and non-invasively. This technology is crucial in helping us design prosthetics that are not only functional, but comfortable and anatomically tailored to each user.

Reaching Remote Communities with Advanced Tools

Mongolia’s vast landscape and sparse infrastructure often make it difficult for patients in rural or nomadic communities to access advanced prosthetic care. The portability and ease of use of the Peel 1 makes it possible for our team to bring scanning capabilities directly to these communities. This flexibility means we can now scan patients anywhere in the country, greatly reducing logistical barriers and ensuring equitable access to our services.

Transformative Impact

This donation significantly enhances our technical capacity and helps us serve more individuals faster and more effectively. By integrating the Peel 1 into our mobile scanning workflow, we can streamline production, reduce turnaround times, and maintain the high standards required for safe and reliable prosthetic devices. It brings us one step closer to our goal of making assistive technology available to every Mongolian who needs it.

A Sincere Thank You to Peel 3D

We are deeply grateful to Peel 3D for their generous and forward-thinking contribution. Their support demonstrates a powerful commitment to global health equity and the life-changing potential of accessible technology. This scanner will have a lasting legacy—helping hundreds, potentially thousands, of individuals regain mobility, independence, and confidence.

For more about Peel 3D and their innovative scanning technology, please visit their website using the button below.

Open Source: Creating a Fully Parametric 3D Scan Compatible Version of the Unlimbited Pheonix Hand

After nearly 30 hours of modeling in SolidWorks, we are excited to release a remixed version of the excellent and proven open-source UnLimbited Phoenix Hand. This update represents a significant step forward for our mission, enabling greater customization while maintaining the robustness and effectiveness of the original design.

The existing versions of the Phoenix Hand are exceptional, supporting a wide range of needs and proving to be a life-changing solution for recipients worldwide. However, through our work with the Mongolian Prosthetics Project, we identified two key areas where a parametric socket design could enhance both the fit and functionality of these devices.

Why a Parametric Phoenix Hand Socket?

Custom Fit with 3D Scanning

Our primary goal was to integrate 3D scanning into our workflow to create the most comfortable and well-fitting prosthetic sockets possible. To achieve this, we developed a solid version of the Phoenix Hand socket, allowing us to use a “combine” command in CAD software to subtract a patient’s limb scan (slightly scaled up to allow for padding). This process enables us to generate a fully customized, printable model quickly and efficiently.More Proportional Sizing for a Better User Experience

While testing this approach, we realized that for patients with shorter, wider residual palms, the existing socket design often resulted in prosthetics that were longer than necessary. This could make the devices appear oversized and slightly inconvenient to use. While some oversizing is inevitable in low-cost prosthetic design, a parametric socket allows us to adjust the length independently of the overall scale—leading to a more natural appearance, improved efficiency, and better comfort for users.

Key Features of Our Parametric Design

Seamless Compatibility – The new socket integrates with the existing Phoenix Hand components, including fingers, pins, and the tensioning system.

3D Scan-Ready – Designed to work within a 3D scanning workflow, enabling precise, patient-specific modifications.

Adjustable Socket Length – The length can be modified independently of global scaling, allowing for a more proportional and comfortable fit.

Improved Strap Integration – Features slots for securing straps, ensuring a stable and secure fit for the user.

We are committed to making this design as accessible and adaptable as possible. The remixed socket is available via the link below and can also be found on Thingiverse, where makers can further refine or customize the model to meet their needs.

By continuing to refine and share open-source prosthetic designs, we hope to empower more individuals with affordable, functional, and well-fitted devices. Thank you for supporting our mission!

Advancing Prosthetic and Assistive Device Manufacturing in Mongolia: A Successful Three-Day Training

It was an incredibly productive three days! Logan Blakeslee, founder of the Mongolian Prosthetics Project, had the honor of leading an intensive 3D scanning, additive manufacturing, and CAD training at the National Rehabilitation and Development Center of Mongolia.

The training was attended by 13 engineers and technicians from all seven publicly funded assistive device workshops across Mongolia. These workshops play a critical role in designing, fitting, and manufacturing prosthetic and orthotic devices provided through the Mongolian Government’s universal healthcare benefit system.

Empowering Technicians with Advanced 3D Printing and CAD Skills

The goal of this training was to provide:

✅ A foundational understanding of CAD, 3D scanning, and additive manufacturing (3D printing)

✅ A practical introduction to how these technologies can be incorporated into prosthetic and orthotic manufacturing workflows

✅ Strategies to improve efficiency, reduce production costs, and accelerate production times

With all branches of the Mongolian National Rehabilitation and Development Center now equipped with 3D printers and scanners, this training was the first of its kind in Mongolia. It provided technicians with the baseline knowledge and tools to enhance existing prosthetic and orthotic manufacturing processes, enabling them to serve more individuals in need.

Logan was incredibly impressed by the dedication, engagement, and technical expertise demonstrated by all attendees. Their enthusiasm for embracing these innovative technologies will undoubtedly contribute to improving access to high-quality, customized assistive devices across Mongolia.

A Shared Commitment to Innovation in Prosthetic Care

We are deeply honored to support Mongolia’s national development of prosthetic and assistive device manufacturing. The expertise and commitment of the National Rehabilitation and Development Center and the Mongolian Government’s investment in emerging technologies are truly inspiring. We look forward to seeing how these advancements are implemented and continuing to collaborate in the future.

A huge thank you to the Oddariya Foundation, the Fulbright Program, the National Rehabilitation and Development Center of Mongolia, and The Mongolian Government for making this training possible! Your support is helping to transform the future of prosthetic and orthotic care in Mongolia.

#Prosthetics #AssistiveTechnology #3DPrinting #CAD #Mongolia #HealthcareInnovation #MedicalTechnology #AdditiveManufacturing #Rehabilitation #UniversalHealthcare

New Workshop: Creating a Lasting Non-Profit Prosthetic and Assistive Device Lab in Ulaanbaatar

We are excited to announce the establishment of a permanent, non-profit Prosthetic and Assistive Device Lab in Ulaanbaatar! This milestone marks a significant step toward providing affordable, custom-made prosthetics and assistive devices to individuals in need across Mongolia.

What Makes This Workshop Special?

Advanced Equipment – The lab is equipped with a 3D printer and a Peel 3D Scanner (donated by Peel 3D), enabling precise production of prosthetics, splints, and orthotics.

Permanent Space – A dedicated workshop ensures long-term sustainability for prosthetic and assistive device production in Mongolia.

Strategic Location – Housed within the Ajin Med office, one of the only private physical and occupational therapy clinics in Mongolia, providing direct access to rehabilitation specialists.

Enhanced Facilities – The space has been rewired for internet access, upgraded lighting, and furnished with support from Ajin Med.

Collaborative Training & Impact

Trained volunteers are actively learning to design and produce assistive devices.

Ajin Med therapists assist in advising prosthetic recipients and are gaining expertise in additive manufacturing.

Students from the Physical Therapy College of Mongolia are being trained in splint, orthotic, and assistive device production.

This collaborative effort is setting the foundation for sustainable, locally-driven prosthetic and assistive technology solutions in Mongolia. By combining cutting-edge technology, expert knowledge, and passionate volunteers, we are working toward a future where everyone has access to the assistive devices they need.

Want to support this initiative? Get involved, spread the word, and help us make a lasting impact!

#MongolianProsthetics #3DPrinting #AssistiveTech #InnovationForGood #ProstheticsLab #PhysicalTherapy #AccessibleTech